Frequently asked questions

Below you will find the most asked questions with detailed answers.

No matter where you purchased your floors from we can install them for you. If you're interested in this service please schedule a free in-home estimate.

Making an appointment is for in-home estimates only. If you're wanting to just look at samples, the best thing to do is go to the showroom and see samples there

1748 W. Anderson Ln. Austin, TX 78757.

Here's a quick link to products:

Here is vinyl plank products that look just like wood

Vinyl Planks

Here's wood floor products

Hardwood floors

It's called The Tile Guy and they host our own sample racks commercial hardwood line called Eco Floor Systems.

Here is the number to Kevin text him when you're going over so he can help you. 5125763535

Or somebody there will help you out whoever's there just go up and knock on the door.

Show him screenshot of what you like

He will bring samples out to the door and you can check them out.

10am-4pm M-Friday

Saturdays 9am - 1pm

When doing wood floors 90% of all homeowners opt for the shoe molding. The reason for this is because most houses will already have an existing baseboard installed and in order to remove baseboards and reinstall them it will require a new paint job for the baseboards and possibly touching up the walls since removing baseboards requires a crowbar and are subject to breaking.

Normally when people want no shoe molding it's because they are replacing baseboards with new ones. In this case we would remove and dispose of old baseboards, then the customer will purchase new baseboards of their choice which we pick up and install towards the end of the installation. Installation of new baseboards costs $2.25 a linear foot of baseboard.

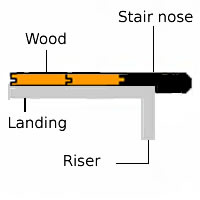

Stairnose

The stair nose is the molding that goes in front of the wood over laping the facing or riser of a step. This piece makes up the edge of a step.

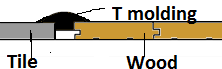

T-mold

A t-molding is the piece of molding that goes in between the wood floor and tile or carpet and other suitable similar flooring such as other wood flooring

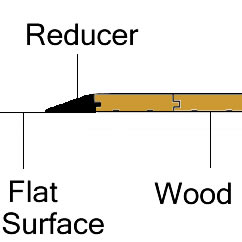

Reducer

A t-molding is the piece of molding that goes in between the wood floor and tile or carpet and other suitable similar flooring such as other wood flooring

When in doubt, you can always count on our frequently asked questions and answers list. If your question is not listed or is not answered to your satisfaction, feel free to contact us.

With so many choices how do you know what's best?

Let's admit it you don't want to be embarrassed by making a wrong decision in floor color or floor product.

The main one, the most important one is color. Our professional suggestion is to pick a neutral light color. Why?

In today's market, designers, builders and remodelers are doing this because it allows them and potential buyers to play with wall color and furniture color from light to dark without worrying about floor color interfering with wall or furniture color choices.

What kind of product should I use vinyl plank , wood, or tile?

Tile is good in showers, kitchen backsplashes and bathroom floors. However when it comes to doing a whole house, people report tile to be colder to the touch and a bit harder to clean vs hardwood or vinyl plank. If you're going to choose a hardwood consider this.

Birch, bamboo, and cork are very soft and can scratch and dent easily. Floors like oak, hickory, and Maple although are better since they are harder, these floors still require an aluminum oxide finish to protect them from being dented or scratched hence the traditional high gloss look.

European oak on the other hand is hard enough to not require an aluminum oxide finish. Often they get an oil finish or a real thin coat of oxide urethane finish for protection. European oak natural color is light so its neutral but also come in darker shades.

European oak on the other hand is hard enough to not require an aluminum oxide finish. Often they get an oil finish or a real thin coat of oxide urethane finish for protection. European oak natural color is light so its neutral but also come in darker shades.

What about solid or engineered hardwood?

If you have a concrete floor do not do solids. Even though solid wood floors may sound like a good idea they are designed to be traditionally nailed on a pier and beem floor. If conditions are not right in a house like not enough air circulation or humidity levels spike, solid floors can cup and buckle even on a second story wood subfloor. On the other hand engineered floors have a crisscross plywood below the thin layer of your real wood to help it stabilize and be water resistant. Engineered wood can be use in kitchens and powder baths.

These floors are designed to get installed in a house with concrete. Furthermore if you have a peer beam house or you want to install hardwoods on a second story floor, gluing engineered wood floors on peer and beam or second story plywood floor is recommended because the engineered floor and glue combination fuses the floor together helping rid of squeaks common on second story or peer and beam floors.

In the past hardwoods especially engineered were often criticized by their thin tops versus their thick top 3/4" solid forefathers. Logic says if you install a soft wood it will eventually dent and scratch so you will need to resand it in the future. Similarly if you install a wood hard enough to withstand wear and tear, it will never require re-sanding. European oak will less likely need sanding because it's rare to dents or scratches. And in case you do dent or scratch one, replacing one plank is much easier than having to resand an entire floor.

What about vinyl plank?

The old vinyl plank floors were thin flimsy glue down planks that required special treatments on subfloor before gluing. Moreover the old vinyl plank floors did not have the depth or look of a real hardwood floor.

Take a look at this vinyl plank floor,. notice how it looks similarly to a hardwood. It's also waterproof, and resistant to dents and scratches. Today vinyl plank floors are just as sturdy and scratch resistant like a European oak. In fact designers, builders, and remodelers alike are starting to do more and more vinyl plank. Vinyl plank floors are water resistant and can be used throughout your whole house including your bathroom floor.

The janka scale is based on a metal ball test. The ball determines the point of damage to the wood. This decides the hardness for hardwood flooring. The janka chart below is available to see the difference.

- Brazilian Ebony 3692 psi

- Brazilian Walnut/ Ipe 3680 psi

- African Pearwood/Moabi 3680 psi

- Bolivian Cherry 3650 psi

- Lapacho 3640 psi

- Brazilian Teak 3540 psi

- Tiete Chestnut 3540 psi

- Tiete Rosewood 3280 psi

- Brazilian Redwood 3190 psi

- Brazilian Rosewood 3000 psi

- Bloodwood 2900 psi

- Brazilian Cherry 2820 psi

- Patagonian Rosewood 2920 psi

- Caribbean Rosewood 2920 psi

- Santos Mahogany 2200 psi

- Tigerwood 2160 psi

- Purple Heart 2090 psi

- Jarrah 2080 psi

- Sydney Blue/ Gum 2025 psi

- African Rosewood/ Bubigna 1980 psi

- Merbau 1925 psi

- Amendoim 1912 psi

- Hickory/ Pecan 1820 psi

- Doussie 1770 psi

- Padouk/ African Cherry 1725 psi

- Kempas 1710 psi

- Bamboo 1650 psi

- Wongo 1630

- Zebrawood 1575 psi

- Timborana 1570 psi

- Cameron 1543 psi

- African Walnut/ Sappele 1500 psi

- Brazilian Maple 1500 psi

- American Maple 1450 psi

- Royal Mahogany 1400 psi

- Caribbean Walnut 1400 psi

- Australian Cypress 1375 psi

- White Oak 1360 psi

- Red Oak 1290 psi

- Caribbean Heart Pine 1240 psi

- Larch 1200 psi

- Teak 1155 psi

- Brazilian Euclyptus 1125 psi

- Peruvian Walnut 1080 psi

- American Cherry 950 psi

- Southern Yellow Pine 870 psi

- South American Lacewood 840 psi

- African Mahogany 830 psi

- Mahogany 800 psi

- Honduran Mahoany 800

When in doubt you can always look up the hardness of a wood floor in the hardness chart below. The janka chart is measured by a metal ball test dropped on wood. Hardwood Flooring FAQ's

Engineered Wood Flooring

Engineered flooring is Engineered wood where only the first layer is solid wood and the rest is a criss cross plywood. It is used for all grades above and below, concrete slab or ply-wood. This makes a perfect floor because its very stable.

The criss cross layers below the solid piece of wood acts as a stable foundation, making it very stable against moisture and elevated levels of humidity. It acts as a 3:1 moisture barrier between your concrete and hardwood.

Most engineered flooring have pretty good thick tops you can sand just as much as a solid. You can't sand past the tongue anyway whether it be a solid or engineered. Plus most if not all engineered hardwood finishes are heat treated at the factory, making the finish 4 times stronger that traditional poly-urethane. That's the reason why most engineered flooring come with a 20 - 30 year wear warranty. The heat treated process cannot be duplicated on site.

Solid Wood Flooring

A solid wood pre-finished or un-finished wood is when a piece of wood is solid from top to bottom. This plank gets nailed down on a wooden sub-floor. It cannot be installed in a concrete surface house. No matter what anyone says, a solid is only designed to be nailed on a peer and beam housing. An expansion gap is important because solid wood expands and contracts easily.

Solid wood floors are meant to get nailed down on top of peer and beam homes. Companies install 3/4" inch plywood on top of concrete flooring all the time and nail down the solid hardwood on top of the plywood. This would act as a base so that a solid can be nailed down onto the plywood. Although this method is practiced on top of a concrete flooring, this method is not recommended by us in anyway. Solid wood floors are meant to be nailed on top of pear and beam foundations where the building is constantly breathing and is not dependant upon an A / C unit to keep it ventilated. Any house that has a concrete floor, will always depend on the A / C unit to keep the artificial environment consistent. Once this changes for any reason like in example:

Reclaimed hardwood is the term used when a wood floor is reclaimed or salvaged as it was probably from an old barn from the American Revolution. It was probably salvaged from a deconstruction, used railroad ties, siding from an old house, old beams from Chicago or an old factory.

Reclaimed flooring in Austin Texas is the term used when a wood floor is reclaimed or salvaged as it was probably from an old barn from the American Revolution. Similar to rustic flooring or handscraped flooring reclaimed flooring may have some history behind it. It can be wood that has been salvaged from a deconstruction, used railroad ties, siding from an old house, old beams from Chicago or an old factory, or sometimes it can be from sunken logs.

Sunken logs or "recovered wood" is another term used differently than "reclaimed wood". The reason is that sunken wood never made it to a processing factory, so its was never used. Another term used is "virgin wood". This type of wood has no nail holes or any kind of history to go with it. Some people might prefer this over the reclaimed flooring and vise versa. It also can come from forest salvaged projects. This can be standing dead tress caused from storms or removed from forest due to urban expansion. These trees are then salvaged in turned into reclaimed flooring.

Reclaimed wood floors use to have some kind of use in the past. Buildings build in the United States in the last 2 centuries used wood as the main structural source. These buildings are now being demolished and wood that comes out of them is being turned into recycled or reclaimed hardwood. Taking advantage of the buildings resources and reusing them again for a different life is a fantastic way to recycle hardwood.

Sometimes people might go locally and reclaim an old barn or an old factory beam. Other people might travel across the globe in search of the perfect floor. Of coarse different regions on the earth will yield different species. For example places in the Pacific Northwest might be yield locally Douglas Fir. While Chestnut, elm or oak might be found more in the Midwest region. Other regions across the globe like in Asia might yield Teak since old buildings there are made of this type of wood.

Reclaimed hardwood is also used in things like furniture, and counter tops.

Benefits of Reclaimed flooring

- The benefits is that it is environmentally friendly. The idea of preserving the forest and avoiding the landfills from wood that comes from these old buildings is a plus.

- Some reclaimed wood come from nearly extinct and exotic wood. For example American Chestnut is a kind of wood floor you cant get anymore because of its nearly extinction due to a blight that happened at the turn of the century. So the only way people can obtain American Chestnut is from reclaimed hardwood. Some other woods that are protected are types of teak from Asia. Some of these teaks you can only obtain from reclaimed hardwood.

- All reclaimed wood floors have a uniqueness to them due to their history behind it. All tell a story and have individuality and character. In fact some are as old as 400 years like the Chinese Elm.

- Some other benefits of reclaimed hardwood is the ability to obtain old growth wood. Some of these woods that took centuries to mature have characteristics not found in younger trees. Getting wood floors from these reclaimed flooring can benefit the forest as less of the older standing remaining tress get left alone. Reclaimed hardwood flooring also come in the engineered form. This makes it possible to install over concrete or in basements otherwise solid wood floors would not be acceptable.

Things to keep in mind when purchasing reclaimed hardwood

- The amount of wood to buy is very important. The reason being is that there is only a few old structures and resources that these reclaimed wood floors come from. It is wise to consider buying allot more than you will need, just in case you will have to do a repair later on down. If you delay this, it may be too late by the time you decide on getting some extra. Keeping around 20 to 40 square feet extra stored away is recommended.

- Also a good practice, but not necessary is to know if the floor you are purchasing comes with a certain certification. For example the (FSC) or Forest Stewardship Council. This organization of makes sure that the reclaimed wood was obtained in a clean responsible manner. The SmartWood program is another organization that validates environmentally friendly practices when obtaining reclaimed timber.

Hand Scraped Wood Austin TX

The handscraped hardwood has the worn look feature with scraped edges and imperfections. This type of plank will hide scratches and dents more than a smooth surface finish. This type of wood resembles the way 100 year old floor will look after it has been walked on for nearly a century.

Rustic wood flooring Austin TX

Rustic hardwoods or the distressed floor used when referring to the worn look of wood floors. Mistaken for the handscraped floor, rustic flooring gives a floor character. Manufactures also consider rustic wood flooring the last of the grade. It does not mean that there is anything wrong with the floor, it just means that the style is different. Million dollar homes install this type of flooring all the time.

Smooth Finish

This type of plank is smooth to the touch and eye. It usually has no imperfection of the top layer surface. The top has been sanded in the factory or in place then finished out making the floor shine due to its smooth surface. Usually this type of flooring may require extra care to protect it from scratching.