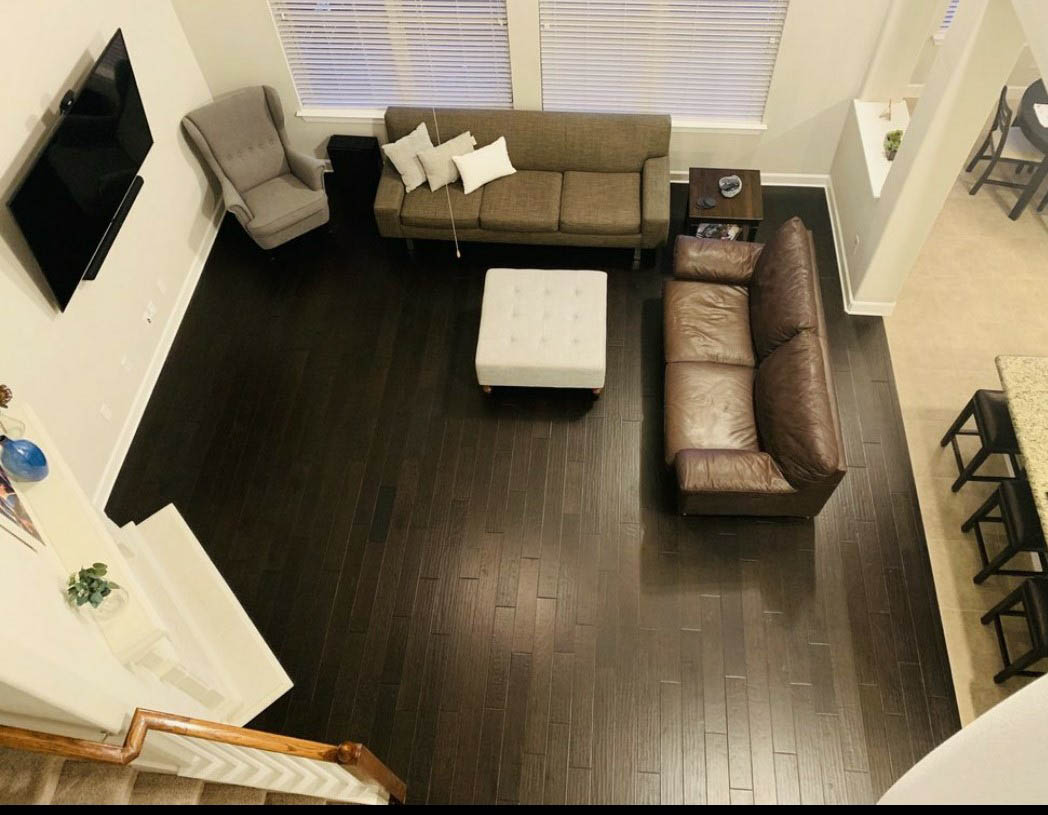

Find the perfect Flooring for your Space, in just a few clicks

Try out our Floor Visualizer app on your phone to see for yourself which of our flooring would fit your space

Try Floor VisualizerPreparation is our trademark.

Preparation is our trademark, see how.

What We Offer

The Latest Product

Styles

Don’t miss out on current flooring styles, classic looks and updated colors that are durable, waterproof, pet friendly and long lasting.

Lifetime-Guarantee

Flooring

Get a custom hardwood, or vinyl plank installation soon as tomorrow and enjoy luxury floors for years to come. Be safe knowing the flooring contractor install is guaranteed.

Get Precise Custom

Estimates

Know what your project will cost, up front with no hidden fees. Mention this offer for a First Time Customer Discount.

Get Floors in 3 easy steps

Get Inspired

See your possibilities by searching through hundreds of floor products and pick out some favorites

Schedule a free appointment

When you have chosen your favorites schedule of free appointment to start the process of making it happen.

We will guide you through

With in days your dream floors will become a reality topped with our lifetime guarantee

Choose from a wide range of looks

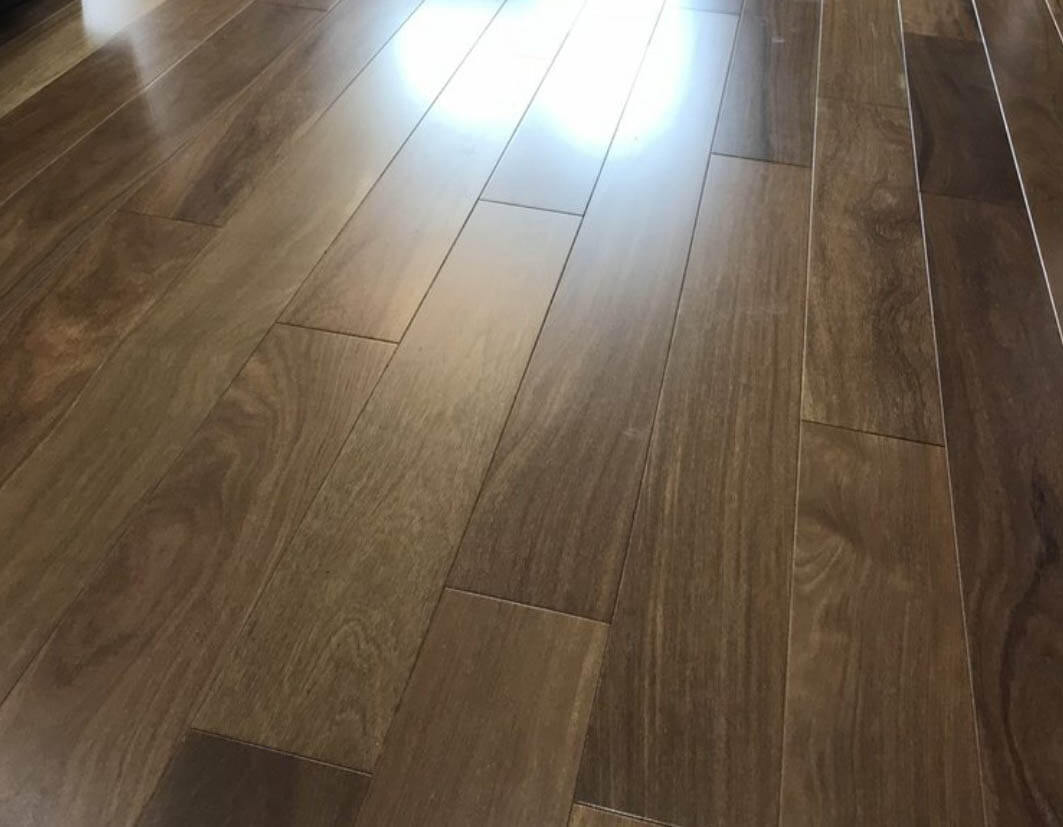

Hardwood Flooring

We stock engineered hardwood, real solid wood floors, European Oak wide planks, and all the latest designer styles.

View Hardwood FlooringVinyl-Plank Flooring

Stock LVP Luxury Vinyl plank floor that is waterproof and pet friendly. Our 3D print products look just like real wood. Discover the latest styles.

View Vinyl FloorsTile Flooring

We can connect you with top quality porcelain, ceramic, and stone tile. Hundreds of mosaics and backsplash flooring wall tile for kitchen and bathrooms.

View Tile FlooringFlooring Made Easy in Austin

Flooring by Need

Find out what floors work best for your lifestyle (pets, kids, durable, eco-friendly).

Flooring by Room

Choose the right color and type of floor for your kitchen, bathrooms, dining room, and more.

Don’t take our word for it

Flooring for Business

Full-Service Commercial Flooring Solutions

We serve businesses of all sizes from corporate and healthcare facilities, to small businesses, and property management groups.

Contact UsFeatured In

Ready to get started?

Schedule your Free In-home estimate